OUR CORE SERVICES.

OUR CORE SERVICES

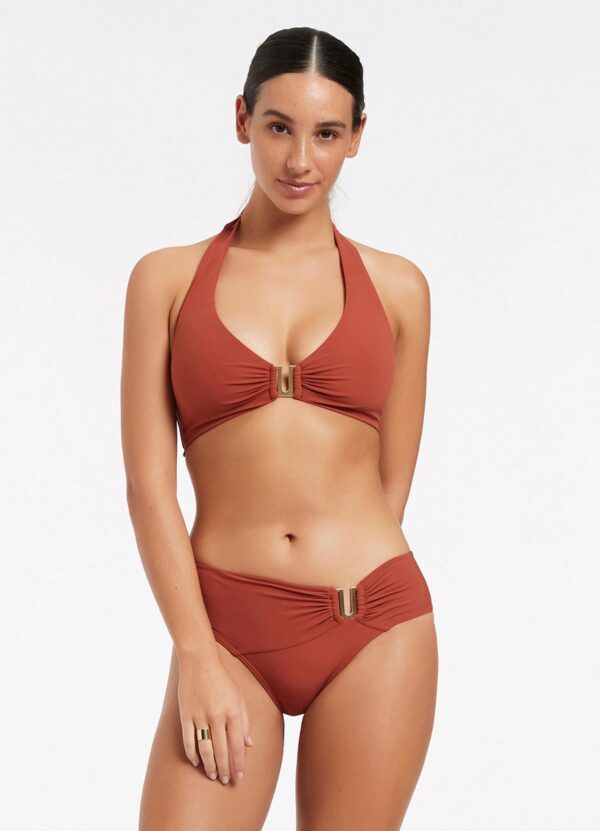

As Swimwear Manufacturers, based in istanbul, we have established ourselves as a leading swimwear brand with a global reach. Our products and services are not only limited to the Turkey, but we have been successfully catering to a diverse customer base from all over the world. Our strong logistics capabilities have enabled us to deliver our high-quality swimwear products and services to customers located in different parts of the world with ease. With our efficient supply chain management, we ensure that all orders are delivered on time and in perfect condition, no matter where the customer is located. This has helped us to build a strong reputation for reliability and excellent customer service, which has enabled us to continue expanding our customer base globally. We are committed to providing our customers with the best quality products and services, and our ability to produce in istanbul while delivering globally is a testament to our expertise in logistics and our dedication to meeting our customers’ needs while manufacturing ethically and sustainably.

PATTERN CUTTING

At Swimwear Manufacturers we develop all of your styles in house. Our team can work from sketches, tech packs, existing samples and reference images etc.

We develop each style from scratch manually. First patterns are made using our recycled paper. Once the first patterns has been tested pattern amendments are required. Our team will then use the fit comments made from the garment fit session to amend the patterns accordingly. Occassionaly we will amend more complicated styles digitally using our pattern cutting programme.

TOILING

Once first patterns are developed, we move on to the next step, toiling. A toile is a fit garment with a purpose of allowing us all to see how the first pattern fits. Its the first opportunity to see each style in 3D form. Normally toiles are made in a cheap fabric for toiling purposes. However at Swimwear Manufacturers we use the final fabrics at the toiling stage. This is the only way you can see how each style fits in the fabric used in production because all fabrics stretch and fit differently. So its necessary to only use the actual fabric that will be used in production.

FABRIC/TRIM SOURCING

We only source our premium quality fabrics from Italy. We have partnered with an amazing fabric manufacturer that produces all of our fabrics using high quality luxe yarns.

They use ECONYL and RPET yarns to make the fabrics. There are multiple different finishes of fabrics we can provide such as matte, shiny, textured and ribbed. Our trims such as clasps and metal rings or sliders are sourced from Portugal and France, again our suppliers use high quality materials and manufacture exceptional grade hardware and trims for us to use in the swimwear we make.

SAMPLING

Once the fit has been tested via a toile and perfected, this will lead to samples being made of each style. At the sampling stage, is where our clients can see each of their styles as a finished collection before moving to the grading stage. Its also a stage where the samples can be tired on different fit models with different body types. Samples allow our clients to test each style in its finished and final form. The finished samples can then be used for photoshoots and creating marketing content for your brand before production begins.

GARMENT FITTING

Once toiles are made, we can organise a garment fit session with our clients. This is a good opportunity for us to go over each toile with our clients. We will identify what fit amendments are required for each style and take a note of this. Doing garment fit sessions with us will make the process much more quicker versus doing a fit session on your own because not all clients know how to measure the changes required.

GRADING

We have invested in a digital system where we grade the patterns, efficiently and at a quicker pace than creating the graded patterns manually, allowing us to move to productions even quicker. We can grade to your own grade rules if you provide them or if you are not sure what grade rules are suitable for your target market, then we can use our own grade rules which we have perfected. We are able to grade for: petite, tall, womenswear, menswear, plus size, childrenswear etc. We provide graded patterns on to card so its ready for production.

LABELLING

We work with a great London based labelling manufacturer, who produces all of our labels for your swimwear. They create fully customised labels. We have various finishings avilable for all of our clients to pick from. Also, we can create custom hang tags and packaging for all clients as well. Creating custom labels, tags and packaging can take up to a month to make so its highly recommended that we organise labelling as early as we can so it doesnt delay production. Please ensure your logos are made as soon as you can.

PRODUCTION

At production is where we layer and cut all of your styles in bulk. We produce your swimwear in-house in London. Production is one of the most exciting stages out of the whole process! The swimwear is made in a production line, this means no finished swimwear is seen until the end of the production line. The way we manufacture production swimwear is compeltly different to how a sample or toile is made. Production line sewing allows the swimwear to be made quicker than how a sample is produced.

WEb Development

Now that you know swimwear İstanbul does it right, let us build your killer website! For your products to sell, the web is your friend. We’ll produce your fashion line and now build your website, end to end! Swimwear İstanbul is always finding ways to help you more.Now we can build your website or e-commerce store!

“Full-Service From Start to Finish

Swimwear & Activewear

Manufacturer”

Full Name

Job Title

FREQUENTLY ASKED QUESTIONS

Q: What is grading?

A: Grading is the process of adjusting a pattern to different sizes, allowing for the production of swimwear in a range of sizes to accommodate various body types.

Q: What is pattern cutting, and why is it important in swimwear manufacturing?

A: Pattern cutting involves creating a template that will be used to cut the fabric pieces for a swimsuit. It is a crucial step in the production process as it ensures that each piece of fabric is cut accurately and efficiently, leading to a high-quality final product.

Q: How does labelling factor into swimwear manufacturing, and what kind of labelling services do manufacturers typically provide?

A: Labelling is essential for branding and marketing purposes, as it allows customers to easily identify and remember a particular swimwear brand. Swimwear manufacturers often provide labelling services, including creating custom labels and tags with a company logo or other information.

Q: Can you describe the swimwear production process from start to finish?

A: The swimwear production process typically involves several steps, including designing the swimsuit, creating a pattern, cutting the fabric pieces, sewing the pieces together, adding any necessary hardware or embellishments, and finishing the garment. Manufacturers may also provide services such as grading, labelling, and quality control to ensure that the final product meets the required standards.

SWİMWEAR MANUFACTURER ISTANBUL

MANUFACTURER

WHAT ARE THE BENEFITS OF MANUFACTURING IN THE TURKEY?

Create your swimwear with us.We are a woman owned and operated business, based in Swimwear Manufacturer, istanbul.

In 2005 marked the end of the Multifibre Agreement, which imposed quotas on how much developing countries could export to developed nations. This led the fashion industry on a hunt for low-cost labour and raw materials, with China, India, Pakistan and Bangladesh, significantly increasing the number of textile exports to markets like Europe and North America. And while the end of the MFA was positive to these countries, it made it even harder for manufacturers in the Turkey to compete in a cost-driven market that is always looking for ways to increase its profit margin.

But especially in the last 5 years and with the rise in spending from younger generations who are much more engaged in environmental and social causes, the fashion industry saw the need to rethink its processes and choices. In 2020 when the pandemic hit, the fashion industry’s wrongdoings were exposed to the world, increasing, even more, the discussions around socially and environmentally responsible fashion. On top of that, supply chains were proven fragile when consumers drastically changed their consumption speed, and all these disruptions caused by the pandemic forced the industry to rethink outsourcing.

While the pandemic and its consequences brought difficult challenges to society and to the fashion industry, it also brought the opportunity to see the benefits of manufacturing in the UK and closer to the final consumer.

Swimwear-Manufacturing-Swimwear-Bikini-Sustainable-Manufacturer

BETTER COMMUNICATION

Being geographically close to your supplier is extremely helpful when it comes to achieving the right product, as it is easier to communicate, visit your supplier and also see in person the development of your product.

Swimwear-Manufacturing-Swimwear-Bikini-Sustainable-Manufacturer

QUALITY

Better communication often leads to good quality products as both the brand and the supplier are constantly in touch. Issues with quality symbolize a huge loss to any business and due to the fact that different countries have different regulations and quality standards, it’s definitely an advantage when your supplier fully understands the expectations your client has in terms of quality.

Swimwear-Manufacturing-Swimwear-Bikini-Sustainable-Manufacturer

AGILE SUPPLY CHAINS AND SHORT LEAD TIMES

One of the main challenges for any fashion brand is how to get the right product at the right time to the end consumer. It often happens that brands do not predict a certain trend and need to design, manufacture and transport clothes within a very short time frame. Working with shorter lead times also allows you to respond quickly to changes in demand by maintaining a healthy stock of products.

Swimwear-Manufacturing-Swimwear-Bikini-Sustainable-Manufacturer

SUSTAINABILITY

Going back to what was previously mentioned, sustainability is nowadays a big purchase driver, especially for the younger generations. When manufacturing closer to home, it is easy to keep track of your supply chain, from sourcing to transport, which enables the company to be certain about how eco-friendly their product is. Transparency is much harder to achieve when you source for materials and then assemble the pieces in different countries because information and data get lost in that process. Manufacturing in the UK gives a brand a competitive edge in terms of both sustainability and transparency.

Swimwear-Manufacturing-Swimwear-Bikini-Sustainable-Manufacturer

LOCALISM

The pandemic brought not only a public health crisis but also a social and economical crisis that will likely last for years. With workers across Britain suffering the consequences of the pandemic, people felt the need to invest in local businesses and in their communities. Buying and shopping locally give customers the assurance that the money they invested in a product will help local workers and the local economy. Knowing where a product came from and that the workers involved in its production had their labour and civil rights protected, is a big purchase driver in the post-pandemic world as well.

With Turkey being regarded as a great quality supplier and with consumer expectations changing rapidly since 2020, manufacturing in the Turkey can be a great source for differentiation and the Turkey fashion industry is likely to invest in manufacturing at home in years to come.

Swimwear-Manufacturing-Swimwear-Bikini-Sustainable-Manufacturer

HOW TO START YOUR OWN SWIMWEAR BRAND?

Creating a swimwear brand follows the same logic as creating any other clothing line, but with some benefits like higher profit margins compared to other clothing categories. With clients eager to finally be able to explore the world again, swimwear brands may have a great opportunity to increase sales and revenues in the near future. To help you plan your first steps, here are some of the key aspects to take into consideration when creating your own swimwear brand:

Swimwear-Manufacturing-Swimwear-Bikini-Sustainable-Manufacturer

BRAND IDENTITY AND VISION

In any highly competitive market, brands must stand out and offer a unique experience, which goes beyond selling good products. Clients want a brand that communicates with them and shares their values and ideas, and so brands must be aware of that when deciding on their vision. The brand’s vision will then guide every piece of the visual identity of the brand: the logo, the packaging, the UX design and the brand’s aesthetic in prints, patterns and design. All of these elements, together, should tell a story that engages the customer and creates brand loyalty.

Swimwear-Manufacturing-Swimwear-Bikini-Sustainable-Manufacturer

FABRICS

Educating yourself on fabrics, trims and hardware is an essential step towards successfully creating a swimwear brand. It is necessary to consider that these materials will be exposed to sunlight, fresh and saltwater as well as chlorine and think about the best possible solutions. There are swimwear fabrics that are sand resistant, dry quickly or offer UV protection, which is a great way of improving the perception of value in a product.

Due to the many aspects that have to be considered and the variety of fabrics, learning as much as possible about the different possibilities is essential to ensure that you are offering your client with a product that suits his needs.

Swimwear-Manufacturing-Swimwear-Bikini-Sustainable-Manufacturer

CREATE YOUR MIX OF PRODUCTS

Deciding on the mix of products is perhaps one of the most important parts of creating a fashion brand, and also one that needs constant evaluation and adjustment. First, take a look at your competitors and try to understand their assortment or mix of products: how many bikinis, swimsuits, cover-up and accessories for example. Doing that analysis can be a great starting point, as it will also allow you to comprehend their price range and how you should position your brand in the market.

This takes us to the administrative part of the business, which is as important as the creative side. First, you must determine your desired retail price, as that will determine how much you can spend on your product, and then create your product mix based on categories, style, option (colourway) and size. Remember to always maintain a healthy mark-up, which should be no less than 3.

Swimwear-Manufacturing-Swimwear-Bikini-Sustainable-Manufacturer

WORK WITH PARTNERS

Trusting your manufacturer is key to the success of any fashion brand. A good relationship with your manufacturing partner allows you to communicate more efficiently and exchange ideas and suggestions. Perhaps the finishing in the spec sheet wasn’t the best one for that product, or maybe your manufacturer has been working with a new kind of fabric that you didn’t know about and that is better quality than the one you originally suggested. Constantly communicating is the best way to ensure that the final product is everything your customer wants.

Although there are many things to consider when launching your own brand, creating a visual identity, developing a mix of products, ensuring a good relationship with your manufacturing partner and understanding the different types of fabric, are a great way to start!

Swimwear-Manufacturing-Swimwear-Bikini-Sustainable-Manufacturer

TIPS FOR STARTING A SWIMWEAR BRAND:TIPS FOR STARTING A SWIMWEAR BRAND:

Starting a fashion brand is no easy task, and creating a swimwear line is no exception. The fashion industry is saturated with brands all trying to get their big break. However, such competition shows that there is a demand for swimwear. It might help to ask yourself what makes your brand stand out from the rest, is there a gap in the market?

Before you begin designing swimwear it is important to bear in mind the specific requirements involved in creating swim garments. You will need to research the most suitable fabrics that hold their shape and are unaffected by chemicals that they are likely to be in contact with such as chlorine and sun cream.

Once you have sourced your fabric it will also be beneficial to select appropriate add-ons for your garment. If you are thinking of adding zips and fringing to the product it is wise to ensure that these additions are fit for purpose. For example, investing in hardware that does not rust, that doesn’t get too hot in the sun and does not easily become detached from the garment. It is notable to research colours, selecting those that do not run. These steps will ensure that your product is of good quality.

One of the most important things to consider when creating a brand is how to make your product stand out from the crowd. One consideration is to analyse consumer habits. Currently, sustainability is a top priority for many consumers. You can make your brand greener by using more sustainable fabrics and methods of production. Not only will making your brand more eco-friendly benefit the environment but your brand will be more appealing to customers who research into how brands are making their manufacturing and production more sustainable.

Put yourself into your customer’s shoes and try to see through the eyes of your demographic. Things that may be important to your consumer may include practical elements of the garment such as fabrics that reflect UV rays, provide SPF protection, are sand resistant and are made of fibres that dry quickly. Think about what is important to you and your brand. You might choose to focus on the aesthetics of your swimwear and opt for flattering cuts and stand out designs.

Deciding to create swimwear does not mean that you are restricted to one product. Consider creating a range that will lead your customer to purchasing further products. For example you may create a beachwear section that allows the consumer to mix and match tops and bottoms and create a complete look with additional items such as a sarong or a beach bag.

Whilst it is beneficial to research your competition and increase your awareness of current trends it is important to maintain a balance between taking inspiration from other brands whilst remaining true to your own ideas. It will be difficult for your brand to stand out if it always one step behind your competition. It might be useful to try and find a gap in the market to elevate your brand from the rest. Decide on a niche market such as creating swimwear for specific body shapes and sizes such as plus size or tall swimwear.

In order to create a successful brand and a high quality product it is imperative that you are properly prepared before you meet with a manufacturer. To be taken seriously and to avoid being taken advantage of make sure that you have a tech pack, know your quantities and create a timeline to present to your manufacturer.

Developing a swimwear line is a complex process that involves a lot of decision-making and forward thinking. However, staying true to yourself and what your brand stands for will give your brand credibility and success.

SWIMWEARMANUFACTURER.ORG